The radiator fairing doors

Monday, 30th April, 2018

It is five months since my last progress report on the model’s challenging twin radiator fairings. In it I described the litho-plate skinning and surface detail. During the past month I have picked up the gauntlet again with view to finishing and permanently installing these two important features of the model, beginning with the completion of the big retractable flaps or doors, a task started the previous autumn. The accompanying images of this phase of the work mostly speak for themselves, so I’ll keep my commentary brief.

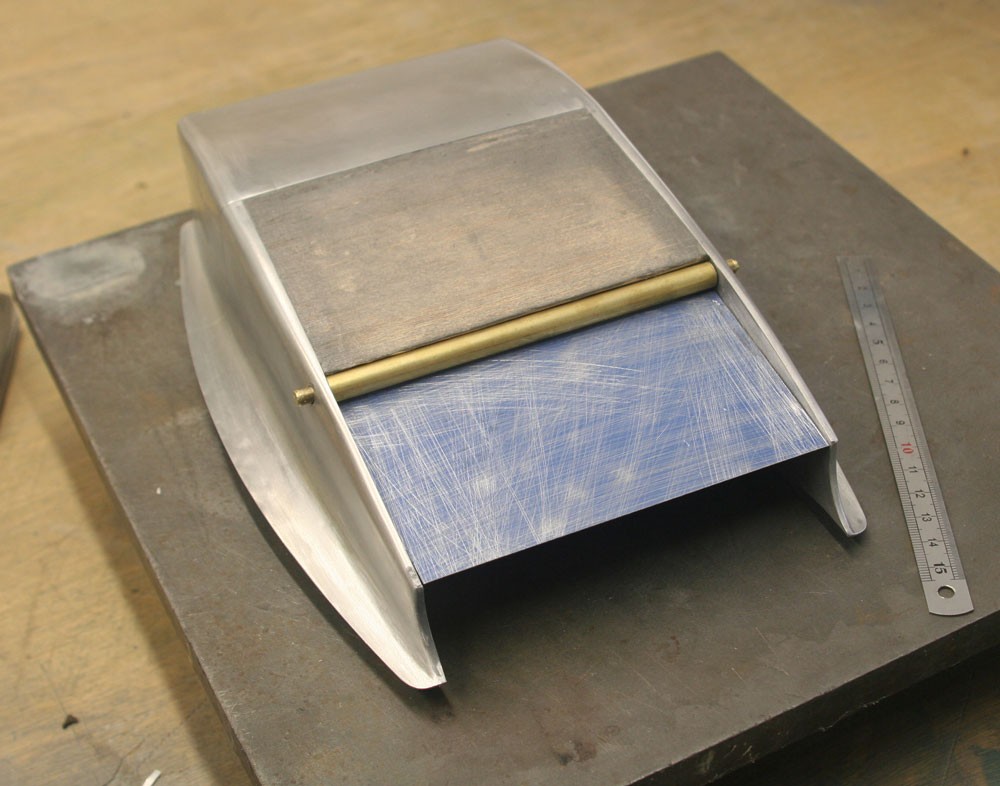

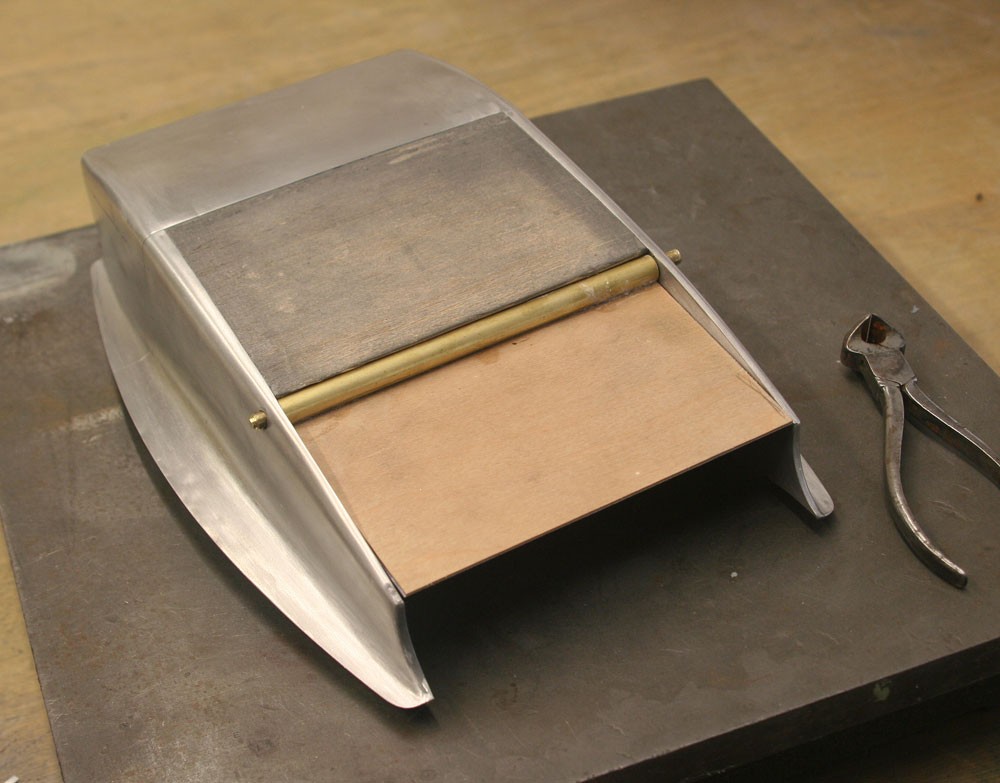

As can be seen, the flap begins as a straightforward rectangle of litho plate with a brass tube tacked with CA glue to the front edge. The tube’s internal diameter is reduced incrementally by telescoping brass tubes, so as to match a pair of short brass pivots that locate through holes in the flanks of the fairing. To this simple base plate I added a layer of 1/6-in. three-ply capped by soft balsa to a depth slightly exceeding the door’s thickness. This composite of wood, litho-plate and generously applied superglue makes for a rigid and resilient structure.

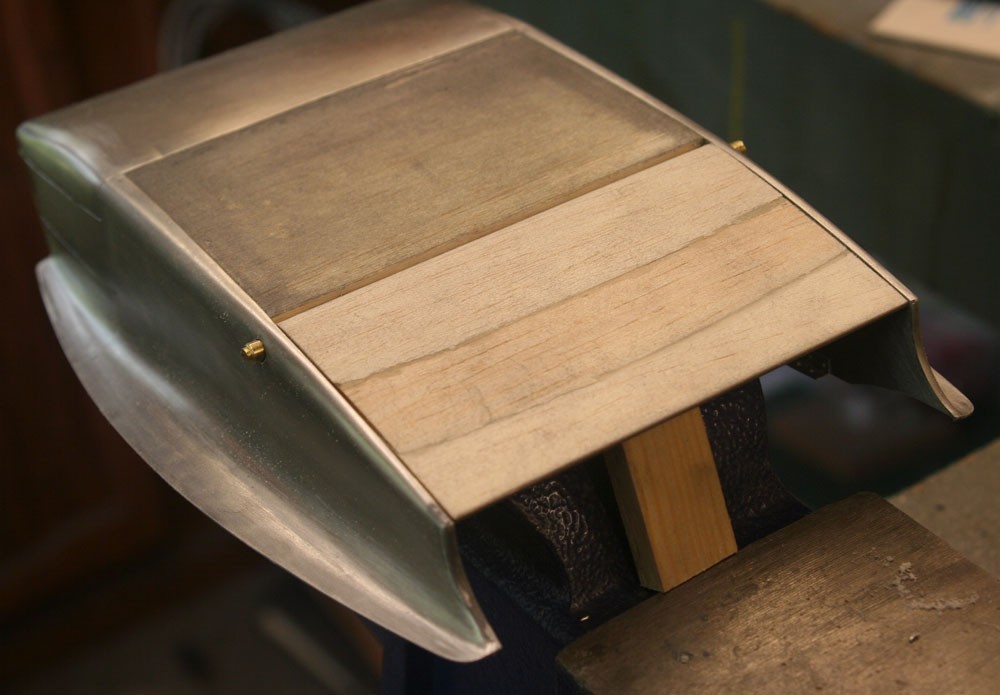

Next I mounted the flap on its pivots and clamped it in the shut position, balsa side outwards, and, using the body of the fairing as a guide, I cut and sanded away away the excess balsa to achieve a smooth tapering shape with a slight convex lateral curvature. The inner surface of the flap, as defined by the base plate is left flat.

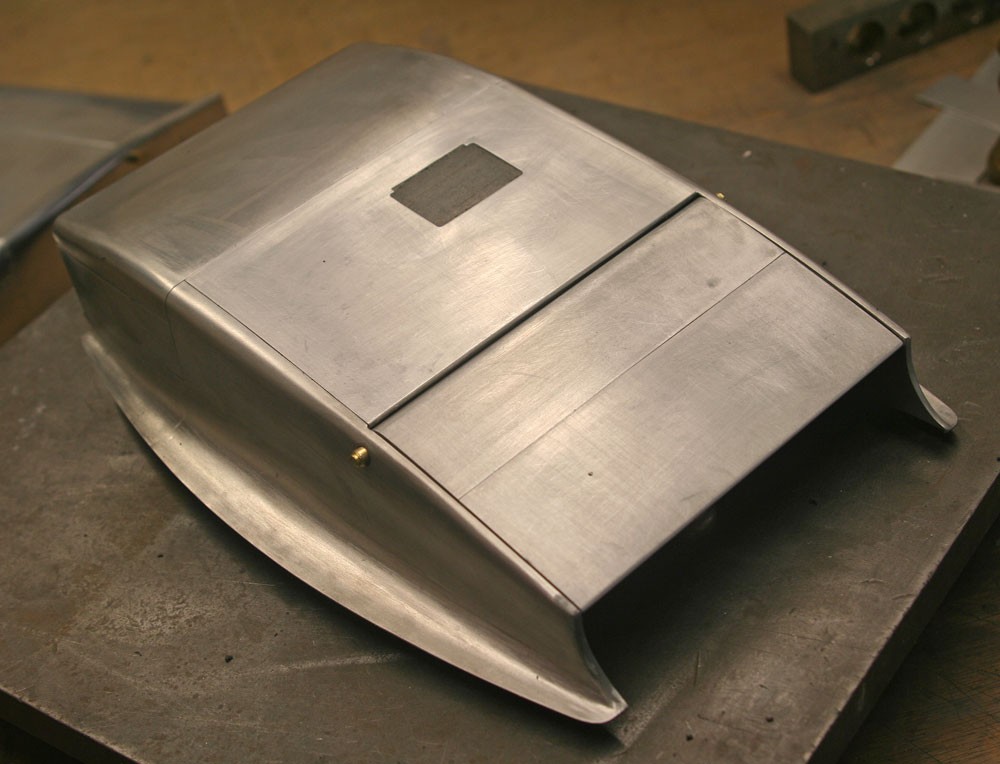

Once satisfied with the shape, I cut and creased the metal skin and folded it in one piece tightly over the sharp trailing edge and back to where there is a seam line, glueing it in place. There was no need for any annealing. The remaining panels were applied top and bottom and curved around the leading edge. Since both doors are to be displayed in the closed position I was able to dispense with any detailing of their the wedge-shaped sides, although I included rivets on the upper face of the flap.

The paired triangular baffles were easily made from folded 0.5 mm aluminium sheet with a circular reinforcing plate riveted at the top. The two bracing members are aluminium tube flattened at either end and secured with 12 and 14 BA bolt sets.