Skinning and fitting the ailerons

Saturday, 14th July, 2018

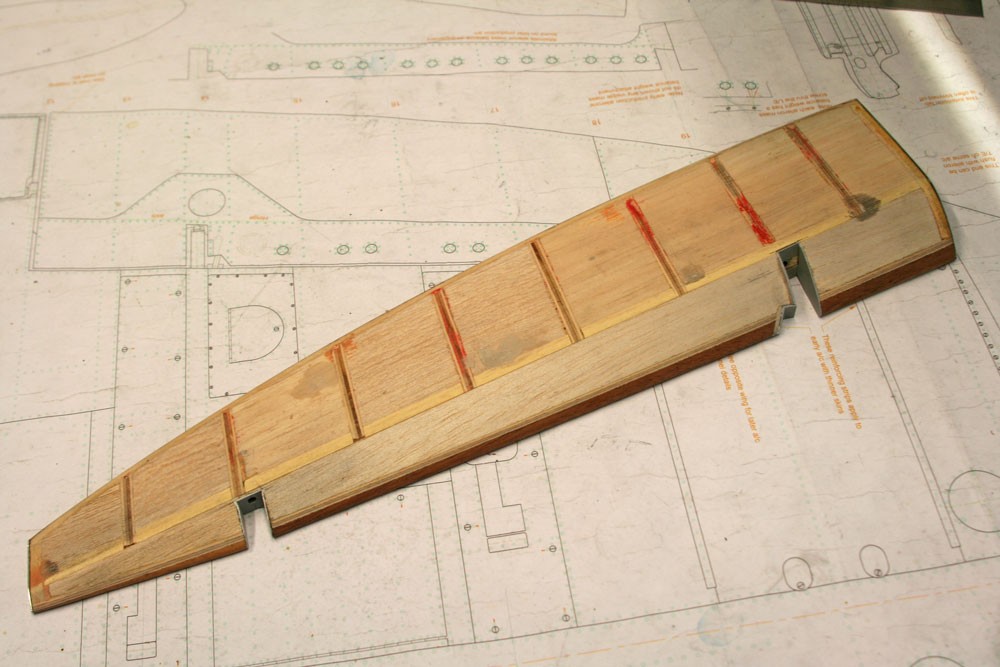

By June this year the wings of my model were complete in almost every detail; by contrast the ailerons remained in a raw state, having languished in storage since the Spring of 2014, when I laid down the main planes in balsa wood and ply. My greatest fear was that over the years some warping or twisting may have occurred, so it was with considerable relief when they slid down over their brass retaining pins with almost perfect alignment.

The first task after some fine tuning of the woodwork was to cut out and line with litho-plate the deep notches in the leading edge that denote the hinge positions, and to face off the inboard/outboard ends of the ailerons with 0.5 mm alloy sheet.

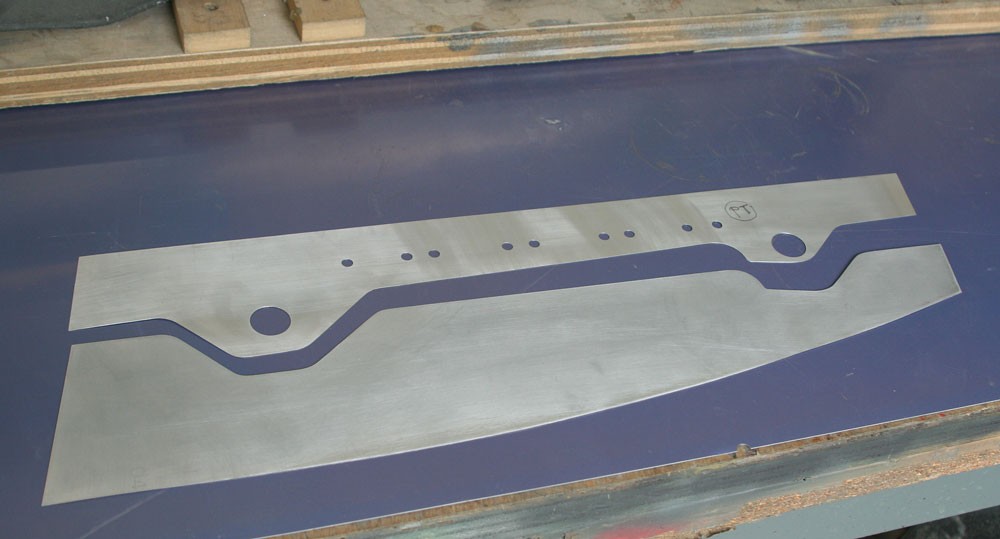

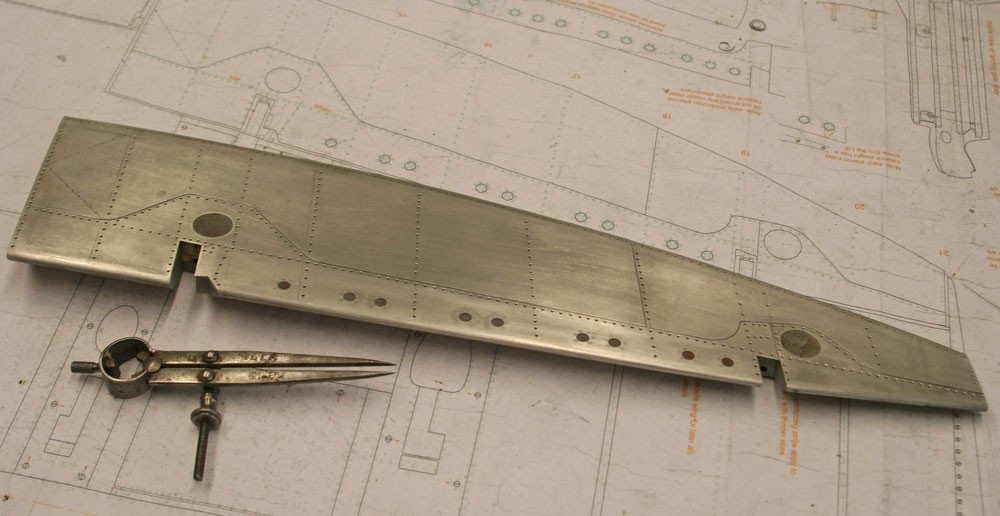

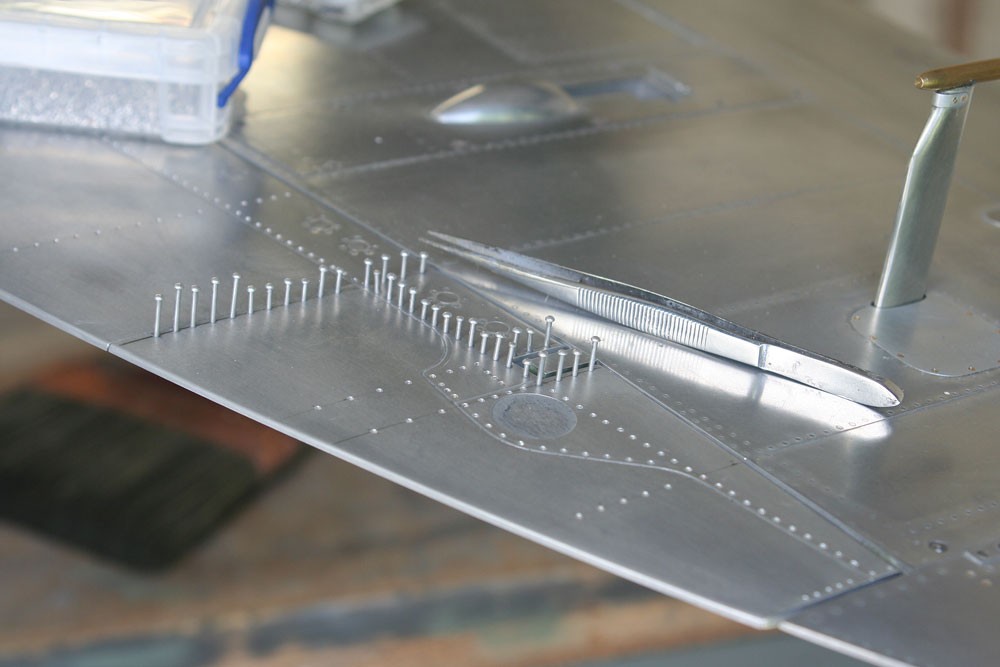

My photos show the arrangement of the skin plates. On the undersurface they are all butt-jointed, which necessitated very careful marking and precise cutting. I began by creating the leading edge strip and used this as a template for marking its rearward counterpart. As a precaution, I carefully annealed along the extreme leading edge, anticipating the sharply upward local curvature. The secret with such delicate work is to keep the torch flame moving all the time; linger for a split second too long and the thin alloy will melt!

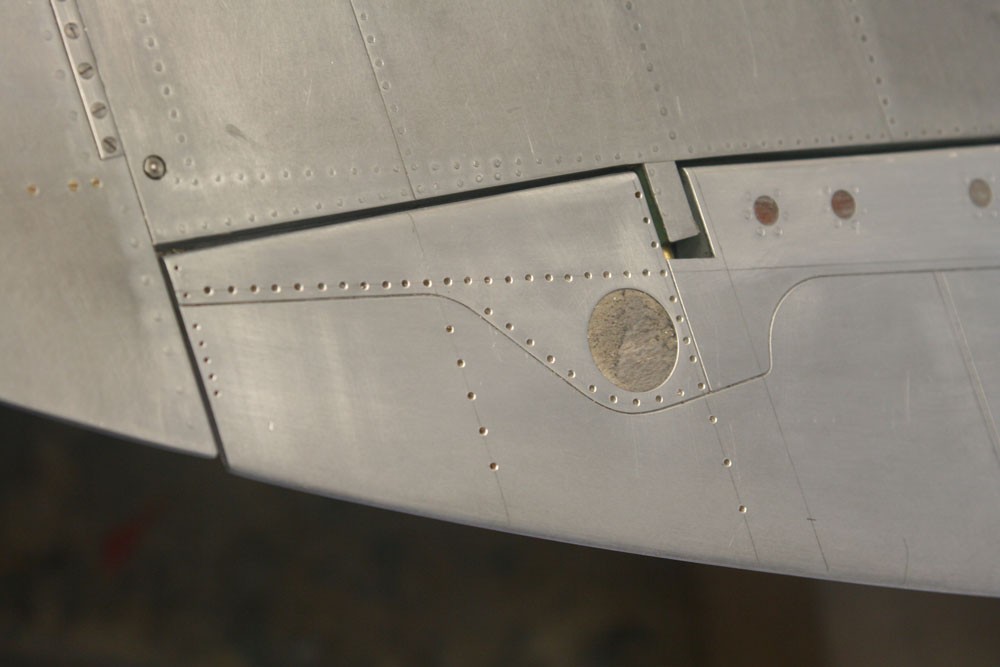

The two leading edge skin panels, having been divided by scoring with a scalpel, were applied first, using contact adhesive reinforced where appropriate by a run of extra thin CA glue. The rearmost panels followed, and I allowed a margin of about 1/16-in. excess all along the trailing edge. Any more would make it difficult to work the litho-plate sharply upwards over the knife-like trailing edge. I used a small hardwood block for this, burnishing upward and along the sweeping trailing edge curvature. When the desired crisp line had been achieved, I consolidated it with more thin CA glue applied from the topside. Once this had grabbed, which happens quickly, I cleaned off the slight fringe of excess metal with a ‘Permagrit’ sanding pad, always stroking inwards toward the body of the piece and never outward, which could rip the metal away again.

The flush rivet detail follows my standard procedure, so there is no need re-state it here. What I would like to highlight is the making of the tiny circular plates aligned behind the leading edge. Their sheer number and diminutive size precluded the cutting of each one by hand, so I used a punch instead. The purist with a mm rule might judge them very slightly oversize. This is because I cut the apertures to match the nearest available punch in my tool kit rather than the precise diameter specified by the drawings. The slight error is hardly noticeable, yet it rendered the job ridiculously easy: all I had to do was to punch eighteen little litho-plate discs and glue them straight into the holes allowed for them. Yes, each one needed flattening on my gauge plate and de-burring with fine steel wool; even so, the entire job took less than half an hour.

The much larger inspection plates, two per aileron, were cut by hand and marked and drilled for tiny 16BA screw fasteners, which are very close to scale size.

The undersides of the ailerons are now complete, and very nice they look; however, I am leaving their upper sides until the model is turned onto its undercarriage to better ensure there is nothing untoward either with their shape or fit.