Near disaster! A cautionary tale

Monday, 8th June, 2015

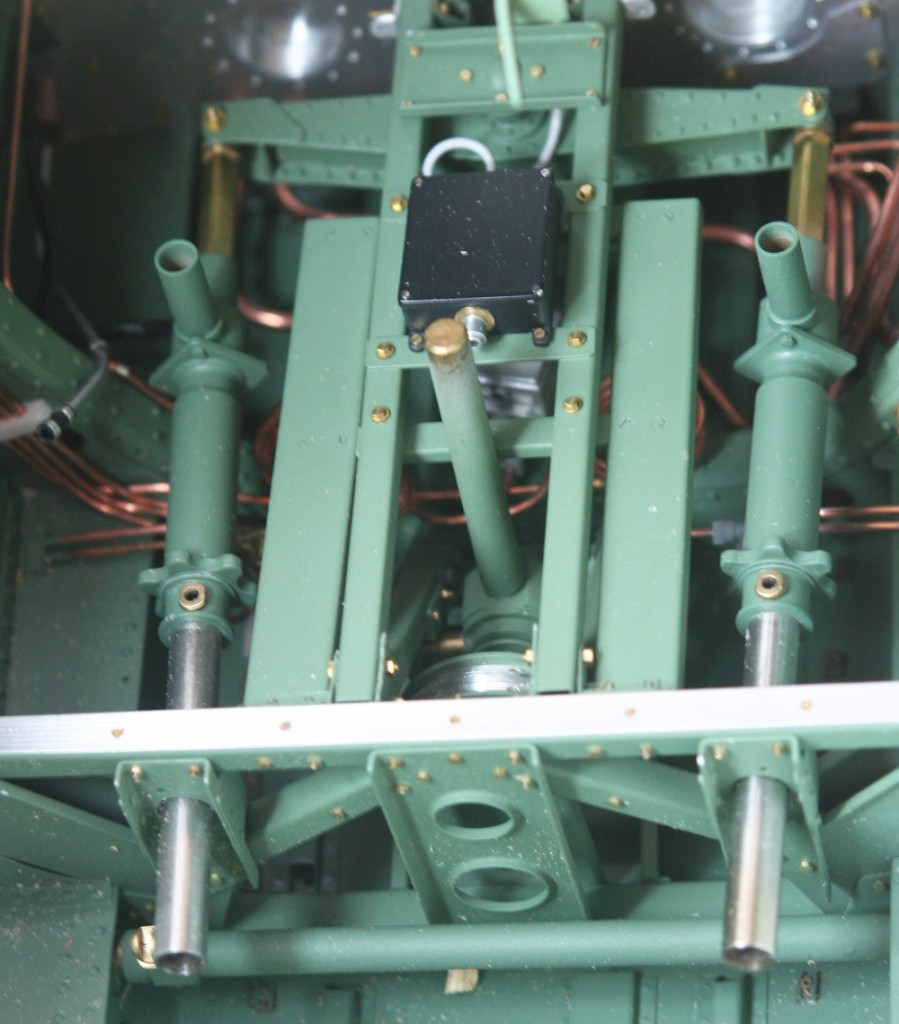

When in 2013 I installed the labyrinthine structure in belly of the fuselage I made provision for future attachment of the control column in the form of a two-inch stub of 7/32-in. round brass, the idea being that at some future time the completed column will telescope neatly down over the shaft and thereby be held securely. In spraying the cockpit most of this stub received coats of paint and varnish.

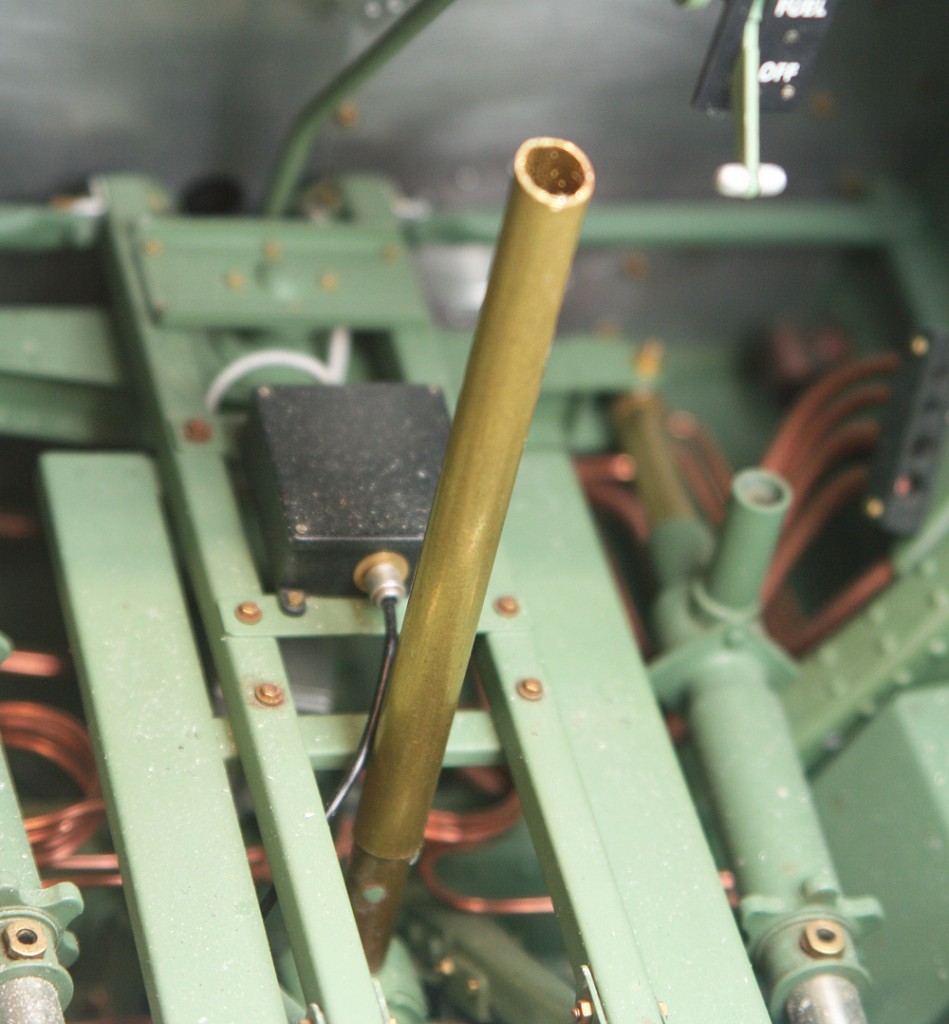

Fast-forward 18 months and I’m ready to build the column. My first task is an inventory of materials. I have a 12-in. length of 7/32-in. ID brass tube, so naturally enough I want to try it. Initially the tube slides on beautifully and I ease down carefully, feeling the paint flake off ahead of it. With about half an inch to go, the brass starts to get tight, so, heeding the signs, I decide to remove it. By twisting the tube gently I can rotate it yet somehow it refuses to come adrift. I apply more pressure but still it won’t budge. Worse, the more I twist and pull, the smaller become the increments of movement.

By now I am applying reckless pressure – which speaks well of my earlier work – but my heart is in my mouth. Just how far can I go? If the heel board support structure gives way, and it might at any moment, with it comes most of the cockpit floor. A repair of this magnitude at this stage would be unthinkable: Three years’ work wrecked in a moment – the ultimate model maker’s nightmare!

The situation is ludicrous: a foot-long length of brass is poking up from out of my beautiful near completed cockpit and there seems nothing that I can do about it; the thing has locked-up rock solid; it might as well be held by superglue.

For a moment I go into panic. I scrabble around for an eyedropper and try introducing a little water. Nothing moves! I find a brush and attempt a hint of WD40 around the base of the tube (God knows what that might do to the paint!). Nothing moves! I light my butane torch and gingerly heat the top of the tube, hoping for expansion. Nothing moves!

I reel at the gravity of the situation, my imagination racing to dark places … so much achieved wasted in an instant. Yet somehow I begin to regain control. I check the external diameter of the snagged brass against the drawing, and it is slightly undersize. Is this a possible solution? Frantically I ransack my stock for thin-walled tube and find an off-cut of the next size up. It fits and is almost exactly the correct external diameter.

If I can’t pull the monster free, then I must cut it off… but how, without doing damage inside the cramped cockpit? The single feasible option is my Proxxon power drill, and chuck a small and very sharp rotary slitting saw, praying it won’t slip or jam. I get Eva to steady the top of the tube, adjust the speed and start the cut. It zips through the thin brass beautifully!

I relate this sad tale partly against myself; perhaps a more prudent model maker would have avoided such a ludicrous trap. Yet it illustrates a universal truth: the more that is invested in a model, or any creative endeavour, the more the maker becomes hostage to fortune. At any stage right up to the end, a single false move or momentary lapse of concentration can send years of work crashing to the ground, and with it hopes and dreams of the builder. It is a sobering thought.