Installing the upper sidewalls

Monday, 28th December, 2015

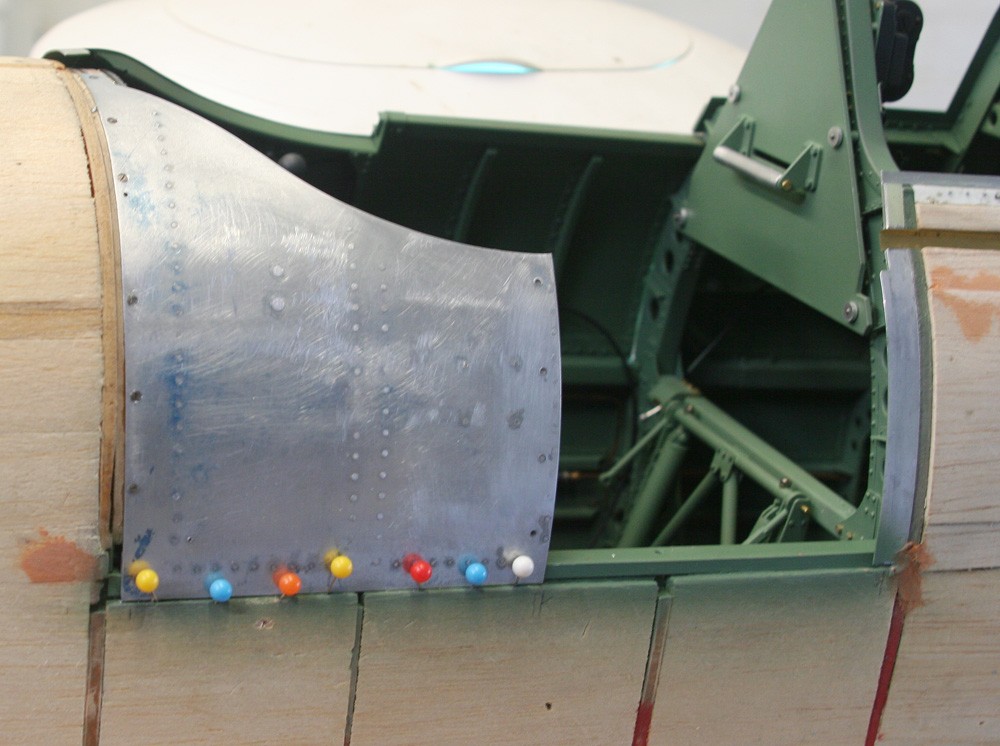

There are certain stages in the saga a scratch built model that change the landscape at a stroke. In the case of my Spitfire Mk IX the installation of the instrument panel followed closely by the enclosing upper cockpit sidewalls is one such event, because it opened the way for me to begin skinning the fuselage with metal and thereby gain a glimpse of the model’s finished potential.

Firstly, however, a potentially tricky piece of surgery: To achieve and retain the required curvature of the port upper sidewall, I built the sub assembly with the cockpit door area integral. Clearly, before installation the ‘door’ needed to be removed, but how without causing serious damage or distortion to the workpiece? In the end I resorted – successfully, I am glad to say – to painstaking and repeated scoring of the 0.5mm alloy with a sharp scalpel blade used against a flexible straight edge.

From then on the task was straightforward: First, after cleaning paint from all contacting surfaces, the panels were glued and pinned into position using viscous cyanoacrylate. The bond was consolidated from the outside by carefully applying very thin cyanoacrylate, which penetrates deep into the joints.

Finally, and with more thick superglue, the entire bare metal exterior of the installed panels was laminated with 1/16” balsawood, which further enhanced structural strength and rigidity. On drying the balsa was sanded accurately, using wood filler where necessary, to fair neatly fore and aft with the existing fuselage lines. Job done!