Wheel bay blisters

Monday, 24th April, 2017

Before moving on to complete the skinning of the wing upper surfaces, two more blisters per wing are needed in the area above the wheel wells. These are relatively easy to make using the simple method outlined in my blog of January 28, and – having described the process already – I can let the photos speak for themselves.

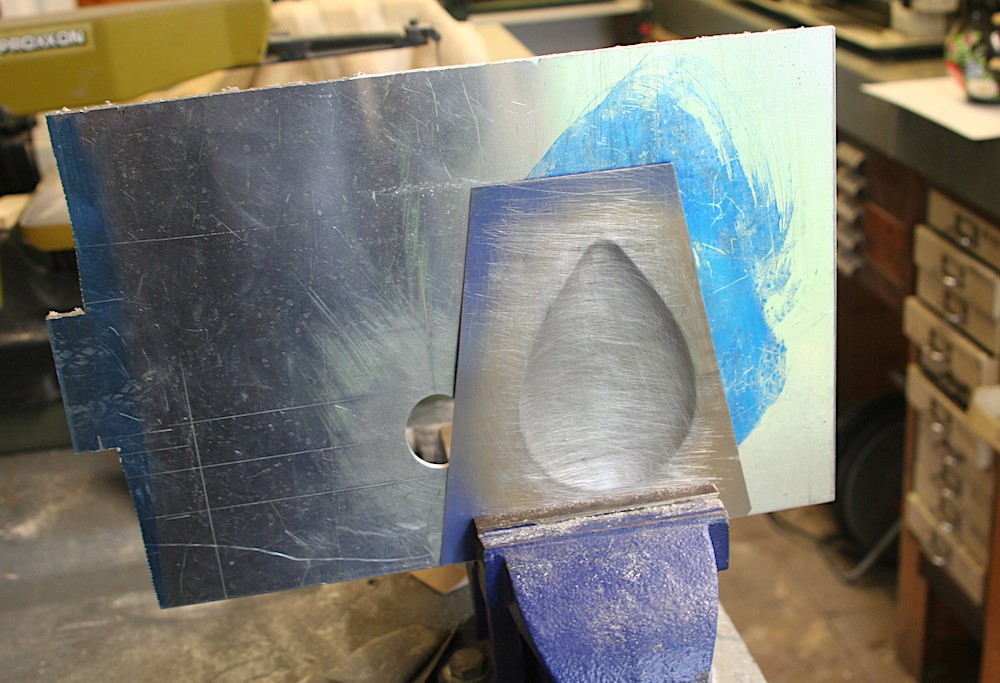

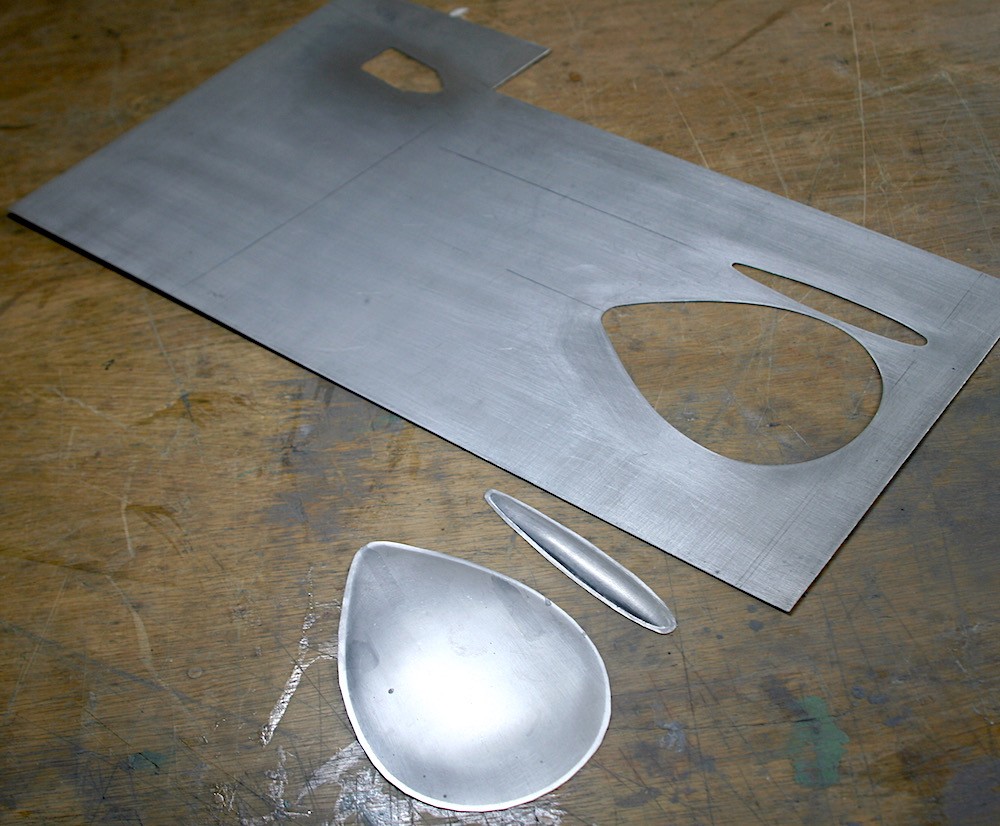

The main departure, however, is that these blisters are formed separately from the skin panel in which they locate, so the template used to cut the forming tool in 1/8-inch aluminium plate is also used to mark out the holes in the skin plate.

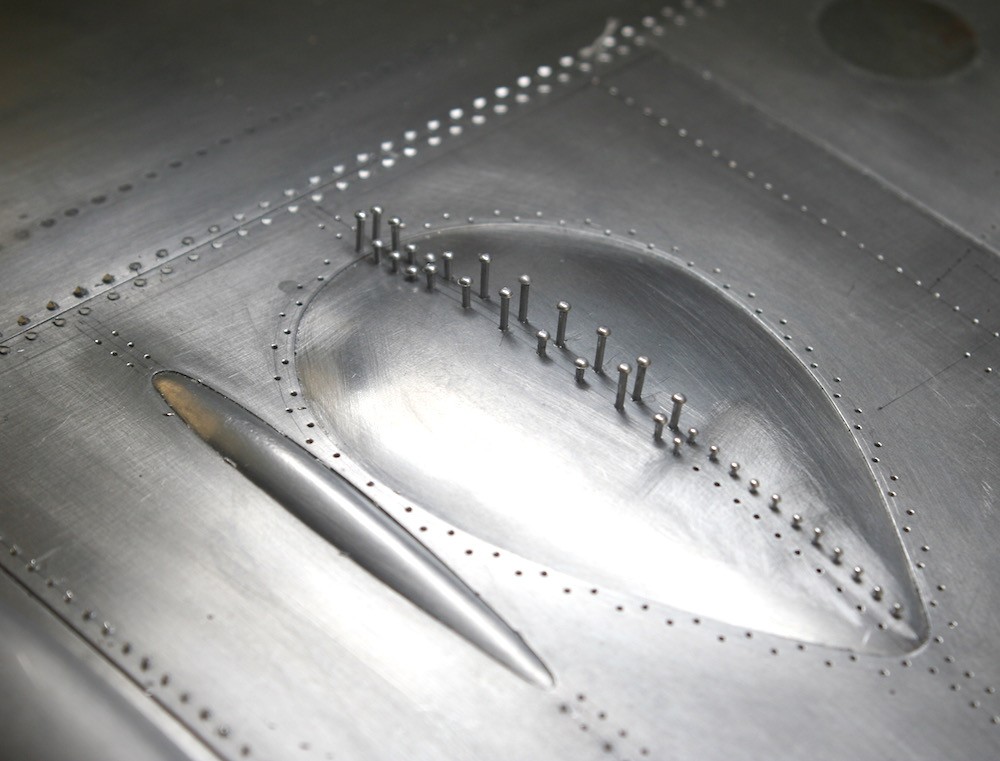

The photos show the narrow flanges left around each blister which allowed me to secure them in position with discrete use of superglue prior to fitting the panel. Once the glue had dried, the flanges were thinned and faired into the skin underside with abrasive paper prior to fitting, thereby ameliorating any slight ‘lumpiness’ that would have been evident had I made them full scale width.